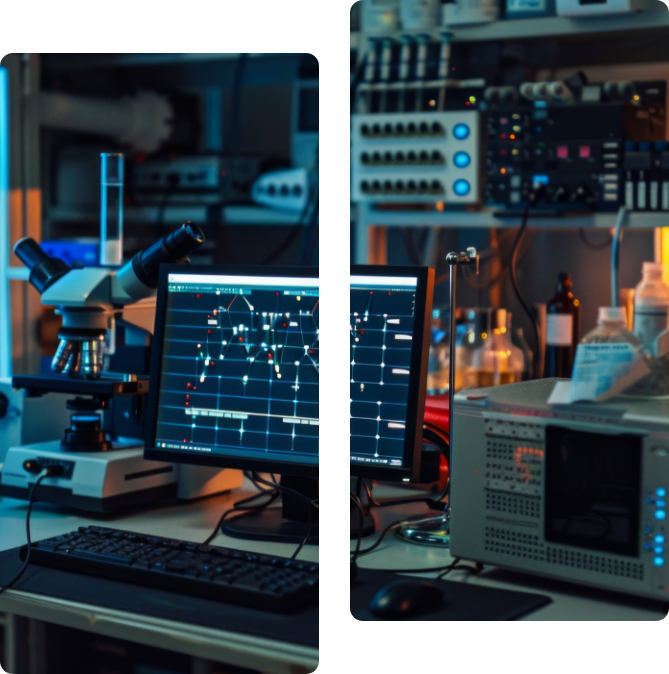

Minakem has been a trusted partner for the pharmaceutical industry, renowned for our expertise in process and analytical development, and seamless scale-up of cGMP intermediates and Active Pharmaceutical Ingredients (APIs and HPAPIs). At the heart of our success is our R&D team operating with a complete toolbox of cutting-edge technologies designed to deliver efficient, scalable and sustainable solutions.

Our R&D capabilities

This diverse skillset is brought together in a collaborative environment, enabling Minakem to tailor solutions for the unique needs of every project. By integrating our R&D team directly with our production sites, we ensure a fast and smooth transfer of processes from laboratory development to industrial-scale. This integration minimizes delays, reduces risks, and delivers unmatched efficiency as your project progresses from early development to commercial production.

Minakem offers flexible production capacities

Ranging from a few kilograms to tens of tons, allowing us to support your API project at every stage of its lifecycle, from preclinical development to commercialization.

At Minakem,

Our broad array of advanced technologies is the cornerstone of our ability to solve complex challenges and deliver innovative solutions. All manufacturing processes are running under stringent current Good Manufacturing Practices (cGMP), ensuring compliance with global regulatory standards.

Our technological expertise includes

Cryogenic Reactions

With capabilities to operate at ultra-low temperatures down to -80°C, we can safely and effectively perform reactions that are highly temperature-sensitive or exothermic enabling the synthesis of complex cGMP intermediates and APIs.

Cyanation and Halogenation

Our expertise in these specialized reactions allows us to incorporate critical functional groups into intermediates, providing key building blocks.

Hydrogenation

With the ability to conduct catalytic hydrogenation at various scales, we deliver high yields and selectivity for a wide range of chemical transformations, including reductions and functional group modifications.

Carbonylation

This powerful technique enables the efficient production of carbonyl-containing compounds, crucial for the development of APIs and intermediates.

Fractional Distillation

Our advanced distillation capabilities ensure precise separation and purification of products, critical for achieving the required quality and purity standards.

Preparative Chromatography

We employ this state-of-the-art purification technology to isolate complex compounds with high precision, supporting development and commercial cGMP productions.

Beyond our technical expertise, Minakem’s commitment to quality and compliance ensures peace of mind for our partners.

All our production sites boast an exemplary quality track record, meeting the stringent requirements of global health agencies and earning the trust of customers worldwide.

With Minakem,

you gain more than

a manufacturing partner

You gain a team of experts dedicated to driving your project’s success. By combining decades of experience, innovative technologies, seamless process development and scale-up, and world class manufacturing sites we deliver unmatched value to your API development and manufacturing needs.