We provide comprehensive Small Molecule API and HPAPIprocess development services, ensuring a seamless transition from early-stage research to commercial manufacturing.

Our fully integrated approach covers every aspect of process development, optimization, and scale-up, allowing us to deliver high-quality, scalable, and regulatory-compliant solutions to our customers.

Comprehensive Process

Development & Optimization

With our 30+ years of experience in API development, our expert R&D teams are well suited to overcome complex chemical, analytical and technical challenges. We focus on innovation and emerging technologies, proactively suggesting alternative synthetic routes to improve process efficiency and sustainability. Our capabilities include:

Route Scouting & Early-Phase Development

We identify and evaluate the most suitable synthetic pathways, balancing efficiency, regulatory requirements, and scalability. Proof-of-concept evaluations ensure feasibility before full-scale development begins.

Process Optimization

We adapt laboratory processes for industrial-scale production, ensuring reproducibility, robustness, and safety. Key supporting activities include solid form studies, impurity identification and markers synthesis, process safety evaluation, analytical method development and validation, and in-depth kinetic and stoichiometric analysis.

Pre-Validation Activities and Validation Readiness

Data generation is critical to support your regulatory filings. We continuously refine processes, integrating Quality by Design (QbD) and Design of Experiment (DoE) approaches to define critical process parameters (CPPs) with a defined Control Strategy to ensure a successful process validation and ultimately, regulatory approval.

Lifecycle Management

We support continuous process improvements, optimize productivity, cost optimization, regulatory updates, and analytical advancements to maintain efficiency and compliance throughout the product lifecycle.

Recognized Analytical Expertise

Our R&D Centers of Excellence house over 60 chemists, kilogram-scale laboratories, and pilot plants that produce non-GMP and GMP batches for supporting toxicity studies, clinical trials and commercial supply for APIs and HPAPIs.

Our analytical development teams work alongside the process chemists to ensure product quality through comprehensive impurity profiling, structural elucidation (HRMS-MS, MS-MS), and robust analytical method development.

Seamless Technology Transfer & Scale-up

We ensure a smooth transition from development to commercial manufacturing through:

Safety Studies

Thorough assessments during development to minimize risks in scale-up.

Process Engineering

A close collaboration between R&D, process engineering, industrialization, and production teams guarantees process robustness and cost-effectiveness.

Pilot & Scale-Up Integration

We determine the appropriate scale-up factors based on your specific program and set a scale-up plan accordingly. We understand that a timely and robust process scale-up is critical for our customers’ success in their development stage.

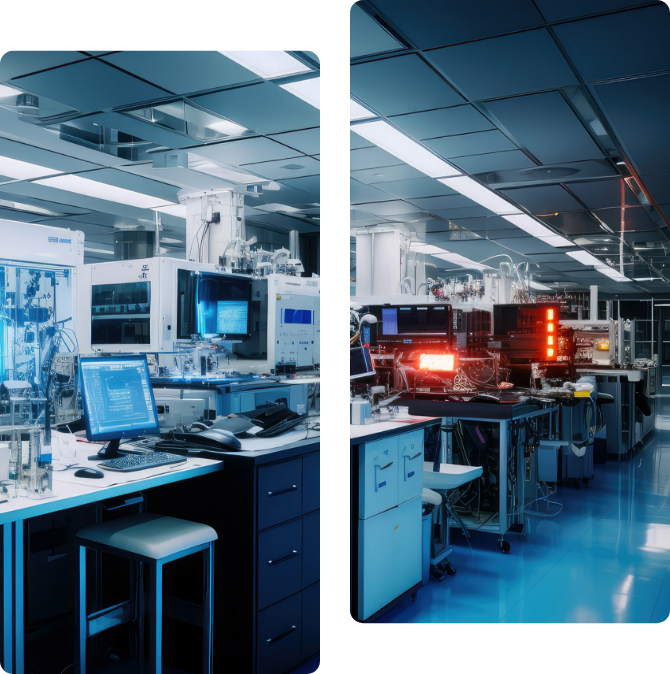

Scientific contributions

We are committed to contribute to the scientific knowledge base through numerous publications of our innovative research in prestigious scientific journals, and by attending world-class symposiums and conferences.

Our dedication to excellence in research and development is reflected in publications and collaboration with academic research groups, which highlight our breakthroughs in chemical synthesis, process optimization, and green chemistry.

Our scientific contribution does not only demonstrate our expertise but also foster collaborations and inspire future innovations, driving progress in the field of drug development, while reinforcing our position as a leader in the chemical development industry.

At Minakem, we combine innovation, expertise, and regulatory excellence to provide end-to-end process development solutions, ensuring successful API manufacturing for our global customers.

Strong Regulatory Expertise

Minakem’s Regulatory Affairs team ensures compliance with global regulatory requirements. We handle the preparation, updates, and submission of CEPs, DMFs, and quality sections of regulatory dossiers.

Together with our customers, we define control strategies and use risk assessment methodologies to support successful regulatory filings.

Focus on Green

Chemistry & Sustainability

As per our Scope 1 and 2 carbon foot-print reduction targets, Minakem is committed to minimizing its environmental impact from the beginning of the R&D study to the final API manufacturing process.

Among the levers at our disposal, the optimization of Process Mass Intensity (PMI), the waste reduction, and the replacement of undesirable solvents and reagents with safer and greener alternatives, are the main courses of action for Minakem’s eco-friendly approach.

Our sustainability-driven approach enhances efficiency while meeting stringent environmental regulations.